What are the technical differences between a Hermetic Hammer Mill and an Impact Crusher?

Difference Between Hermetic Hammer Mill and Impact Crusher

- Working Principle:

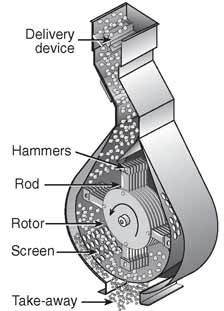

- Hermetic Hammer Mill: Utilizes high-speed rotary hammers that impact material to pulverize it. Material enters the mill chamber, where it is impacted by the rotating hammers and forced against a grinding plate or screen.

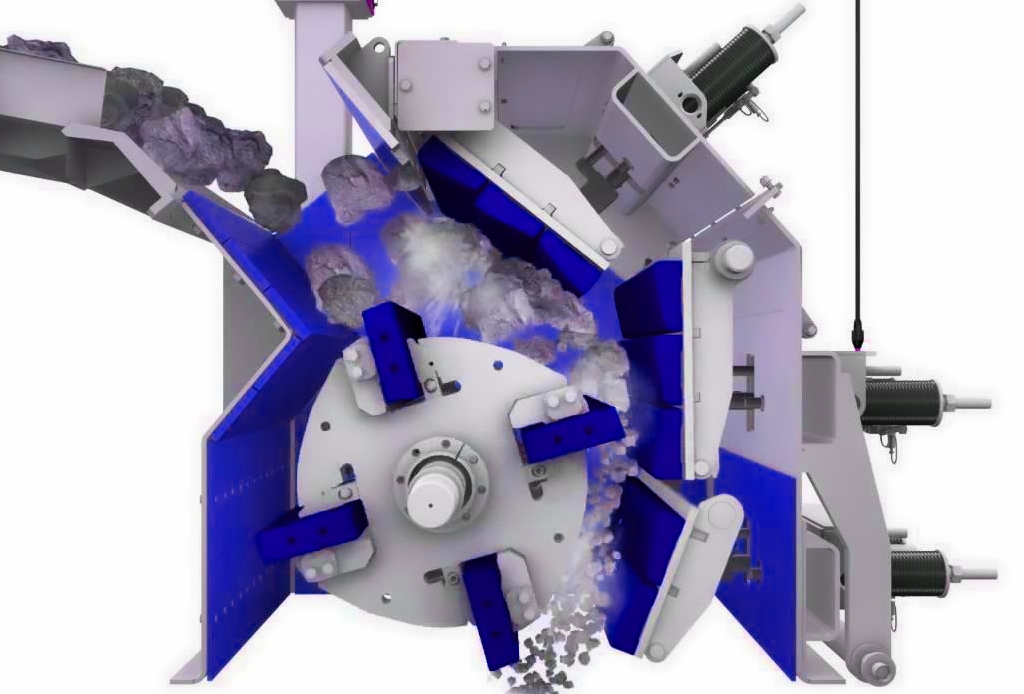

- Impact Coal Crusher: Uses impact energy for crushing. A high-speed rotor with blow bars strikes the material, throwing it against impact plates, breaking it into smaller pieces through successive impacts.

- Design:

- Hermetic Hammer Mill: Features a series of swinging hammers attached to a rotor, all enclosed in a hermetic (airtight) housing to prevent dust emissions, with a perforated screen for precise size control.

- Impact Coal Crusher: Incorporates a solid rotor with rigid blow bars. The housing is vented, and it doesn’t require a screen, as material exits through designated openings.

- Purpose:

- Hermetic Hammer Mill: Suitable for fine and medium grinding of biomass, grains, and wood chips. The hermetic design is ideal for materials that require dust containment or a controlled processing environment.

- Impact Coal Crusher: Specifically used for crushing coal and other materials with high compressive strength, intended for coarse and medium-sized crushing applications.

- Product Size and Adjustability:

- Hermetic Hammer Mill: Output particle size is controlled by changing the screen, typically resulting in a fine to medium grind.

- Impact Coal Crusher: Output size is adjustable by altering the gap between the rotor and impact plates, which is effective for producing coarser material for further processing or as boiler fuel.

- Material Suitability:

- Hermetic Hammer Mill: Handles a variety of materials, such as biomass and agricultural residues, with a design that effectively contains dust and prevents dust explosion hazards.

- Impact Coal Crusher: Engineered to crush hard, brittle materials like coal and stones. It is not suitable for fibrous or light materials, as it relies on impact crushing.

- Efficiency and Application:

- Hermetic Hammer Mill: More energy-efficient for softer, fibrous materials, providing consistent size reduction in biomass or feed processing.

- Impact Coal Crusher: Offers higher efficiency for hard, brittle materials like coal, suitable for mining, power generation, and other heavy industrial applications.

- Environmental Control:

- Hermetic Hammer Mill: The airtight housing helps contain dust emissions, making it suitable for indoor use and environments where dust control is crucial.

- Impact Coal Crusher: Not fully enclosed, which means dust emissions are likely, requiring external dust suppression systems for environmental safety.

Summary: Hermetic hammer mills are best for fine grinding applications involving dust control, especially for biomass and fibrous materials, while impact coal crushers are ideal for crushing hard, brittle materials such as coal, providing effective coarse or medium-size output.