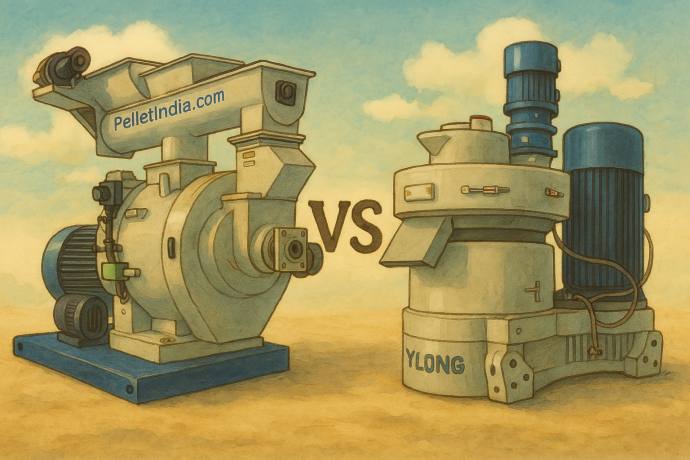

What generation level does the PELLETINDIA 3022-2.5 pellet mill represent compared to Other 8th Generation ?

The PELLETINDIA 3022-2.5 and the 8th Gen Other’s Pellet Mill (160 kW) are two different models from well-known pellet mill manufacturers — PELLETINDIA (Servoday Plants & Equipments Limited) from the Gujarat, India and Other’s from China. Here’s a detailed comparison of their design, performance, build quality, and pellet output characteristics such as GCV and density:

🔧 1. Design & Engineering Quality

| Feature | PELLETINDIA 3022-2.5 | Other’s 8th Gen (160 kW) |

| Origin | Make in India (High-grade industrial engineering) | China (Mid-range, mass-production focused) |

| Build Quality | Heavy-duty cast steel, designed for 24/7 industrial operation | Lighter frame, suitable for medium-duty operation |

| Pellet Mill Type | Ring Die, Gear-Driven | Ring Die, Gear-Driven |

| Gearbox | One-piece cast gearbox, with pressurized lubrication, very durable | Gearbox with standard oil bath, less durable under heavy loads |

| Service Life | 10-15+ years with maintenance | 4-6 years with maintenance |

✅ Verdict: PELLETINDIA 3022-2.5 is better engineered for long-term industrial use.

⚙️ 2. Motor & Power

| Specification | PELLETINDIA 3022-2.5 | Other’s (8th Gen) |

| Main Motor | 160 kW (Siemens/ABB class motors) | 160 kW (typically Chinese brand motors) |

| Feeder + Conditioner | Separate motors for precise control | Integrated feeding, less control accuracy |

✅ Verdict: Both use 160 kW, but PELLETINDIA’s motor system and feeding precision are superior for quality consistency.

🔄 3. Output Capacity

| Parameter | PELLETINDIA 3022-2.5 | Other’s |

| Wood Pellets (High density) | 2.2 to 2.5 TPH (actual consistent) | 1.8 to 2.2 TPH (variable) |

| Biomass Pellets (mixed materials) | 2 to 2.5 TPH | 1.5 to 2 TPH |

✅ Verdict: PELLETINDIA is more consistent under full load, especially for high-density materials like wood or torrefied biomass.

🌡️ 4. Pellet Quality: GCV, Density & Durability

| Metric | PELLETINDIA 3022-2.5 | Other’s |

| Pellet Density | 650–750 kg/m³ | 600–700 kg/m³ |

| GCV Output Potential | Higher due to compression & die precision | Moderate due to less compaction pressure |

| Pellet Durability Index (PDI) | 95–98% (very high) | 85–90% (medium-high) |

✅ Verdict: PELLETINDIA produces denser, harder, and higher energy pellets. Better for exports, industrial boilers, and power plants.

🔧 5. Die & Roller Design

| Aspect | PELLETINDIA | Other’s |

| Die Quality | European standard, chrome-alloyed dies | Chinese-grade dies, shorter life |

| Changeover Time | Quick-change system, efficient | Manual, more downtime |

| Spare Parts Life | Longer (800–1200 hours) | Shorter (400–600 hours) |

✅ Verdict: PELLETINDIA die/roller assembly is more durable and produces uniform pellets.

🛠️ 6. Maintenance & Downtime

| Feature | PELLETINDIA | Other’s |

| Maintenance Required | Less frequent, mostly preventive | Frequent due to part wear |

| Automation | Advanced lubrication, grease pumps | Manual or basic automatic greasing |

✅ Verdict: PELLETINDIA minimizes downtime with easier maintenance and automation.

💰 7. Cost & ROI

| Item | PELLETINDIA 3022-2.5 | Other’s |

| Initial Cost | Higher (Premium Machine) | Lower (Budget Option) |

| Operational Cost | Lower over time (due to durability) | Higher (frequent part replacement) |

| Return on Investment | Higher ROI if running 24/7 | Suitable for small to mid-scale projects |

🏆 Final Recommendation: Which is Best?

| Application | Best Choice |

| Industrial Pellet Plant (24×7, export quality) | ✅ PELLETINDIA 3022-2.5 |

| Medium scale, local market, budget-conscious | ✅ Other’s (8th Gen) |

| Pellet Density, GCV, Long-Term Durability | ✅ PELLETINDIA 3022-2.5 |

| Initial Budget-Friendly Setup | ✅ Other’s |

✅ However, in terms of technological maturity and evolution, the PELLETINDIA 3022-2.5 can be considered:

🔹 Equivalent to or above the 10th generation level compared to other Chinese brands.

🟢 Conclusion

If quality, GCV, pellet density, and long-term ROI are priorities — PELLETINDIA 3022-2.5 is superior.

If you’re setting up a budget-friendly project for local biomass or cattle feed pellet use — Other’s is adequate.

🔒 Disclaimer

The comparison presented is based on available technical specifications, field performance data, and industry experience. PELLETINDIA, a division of Servoday Plants & Equipments Limited, has compiled this information for educational and informative purposes. While every effort has been made to ensure accuracy, this comparison reflects the perspective of PELLETINDIA and may not fully represent the proprietary claims or updates from Other’s or its affiliates. All trademarks and brand names used are the property of their respective owners.

For verified technical details, users are encouraged to consult the original manufacturers.

📞 Contact Us for Biomass Solutions

📍 Servoday Plants & Equipments Limited

📞 +91 9427210483 | +91 9427210484

📧 [email protected]

🌐 www.PelletIndia.com

👤 Contact Person: Sanjay Masuria

📲 WhatsApp: +91 9427210483

From Concept to Commissioning. We are with You.

Our policy is simple and transparent:

No undersized parts, no fraud, no fake components—genuinely serving since 1969. 🚀🔥