Introduction

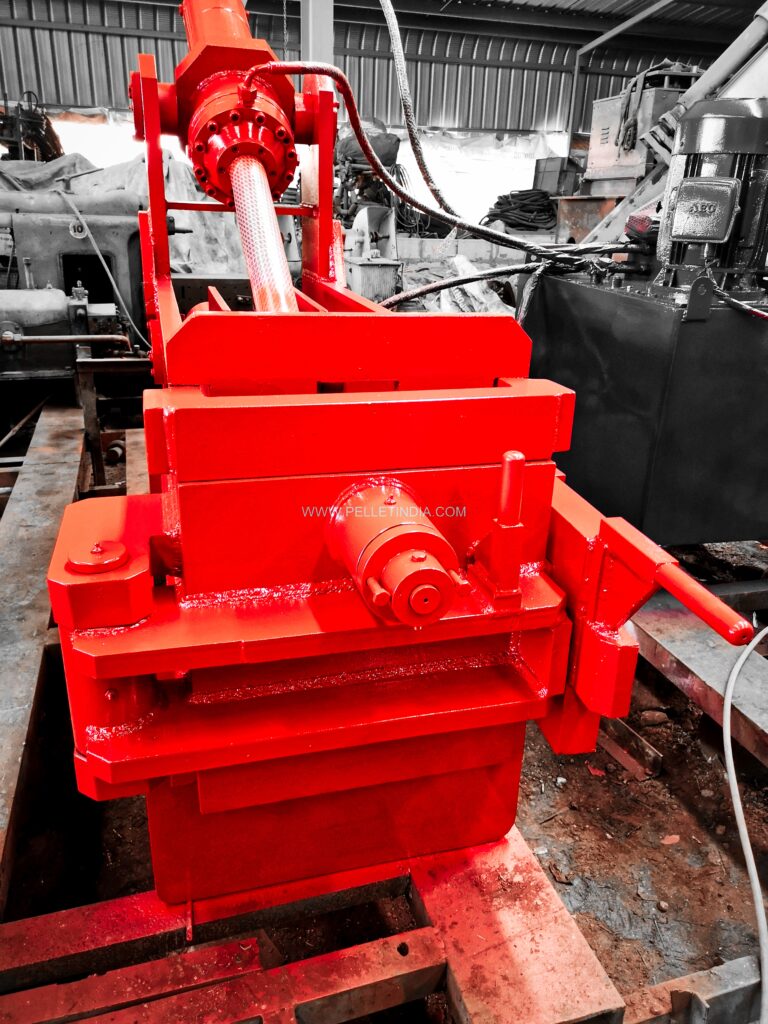

The Baling Press, also known as a baling machine, is designed to compress scrap metal and waste materials into dense blocks, simplifying storage and transportation. These machines are capable of handling both ferrous and non-ferrous metals, significantly reducing costs and easing the handling process. By using hydraulic pressure, the Baling Press increases the density of scrap, making it easier to transport and melt down in furnaces. Our advanced baling presses are available in both semi-automatic and automatic models, offering efficient and time-saving solutions for metal scrap management.

Features

Our Baling Presses are engineered with the latest technology, focusing on durability, ease of operation, and cost reduction. They come in various models, including Continuous Baling Press, Triple-action, Double-action, and Single-action presses, tailored to meet specific scrap management needs. These hydraulic machines feature powerful compression capabilities, reducing scrap to compact, manageable sizes. Automated and semi-automated options ensure smooth operation, reducing manual labor and enhancing productivity. Additional features include customizable pressure settings and sturdy construction for long-lasting performance in demanding industrial environments.

Uses

The Baling Press is widely used across industries such as scrap yards, rolling mills, and manufacturing units where metal waste is generated. It is an essential tool for recycling operations, enabling the efficient handling of materials like steel, copper, aluminum, and other metal alloys. These presses are particularly useful in industries requiring high-density scrap for melting in furnaces, as they improve furnace loading efficiency. By reducing the bulk of scrap metal, Baling Presses also cut down on transportation costs, making it easier and more cost-effective to move large quantities of material.

Raw Materials

The Baling Press is capable of processing a wide range of metal scraps, including steel, copper, zinc, iron, stainless steel, mild steel (MS), and aluminum, among others. It efficiently compacts both ferrous and non-ferrous materials, creating uniform, dense bales ready for transport or further processing. These machines are ideal for industries that generate metal scrap regularly, such as manufacturing units, scrap yards, and metal recycling facilities. Whether dealing with large volumes of mixed metals or specialized materials, our baling presses deliver reliable, high-quality results tailored to the specific requirements of each operation.