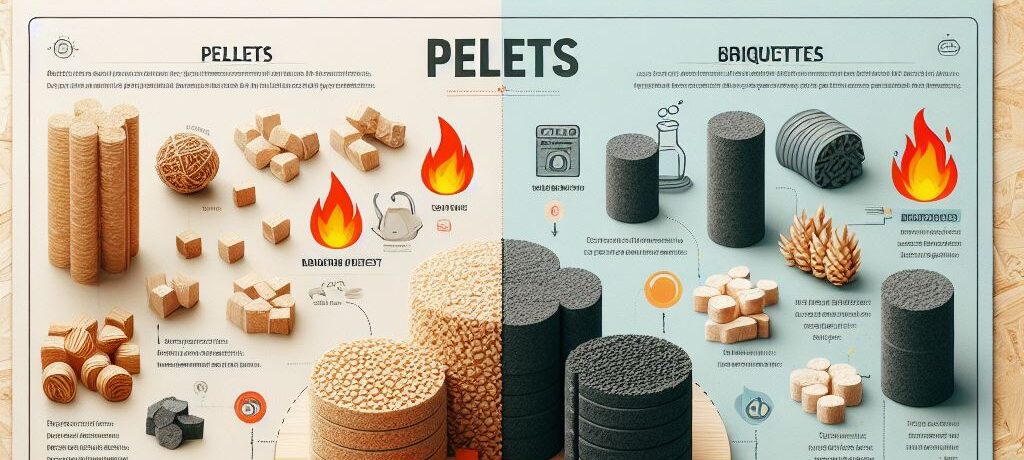

Biomass Pellet vs Briquettes ?

Both biomass pellets and briquettes are compressed forms of organic materials used as a renewable fuel source. Here’s a breakdown of their key differences to help you understand which might be a better option:

Shape and Size:

- Pellets: Cylindrical or cubical with a small diameter (6-12mm) and uniform size.

- Briquettes: Varied shapes (logs, rectangles, etc.) with a larger diameter (typically 50-90mm) and can have size variations.

Production Process:

- Pellets: Made under high pressure and heat, forcing biomass through a die to create uniform pellets. Requires grinding the biomass into a fine powder before pelleting.

- Briquettes: Compressed using mechanical or hydraulic pressure, sometimes with a binder to improve cohesion. May require less processing of the biomass compared to pellets.

Burning Characteristics:

- Pellets: Higher density due to the production process, leading to more consistent and efficient burning with lower ash content. Easier to handle and automate feeding into boilers or stoves.

- Briquettes: Looser structure can result in slightly lower burning efficiency compared to pellets. May require more frequent refilling in furnaces or stoves.

Moisture Content:

- Pellets: Lower moisture content (typically below 10%) due to drying before pelleting. This improves storage life and burning efficiency.

- Briquettes: Can have a slightly higher moisture content (up to 15%) depending on the production process. May require drier storage conditions.

Cost:

- Pellets: Generally, require more processing and energy for production, often leading to a slightly higher cost per unit weight.

- Briquettes: Production can be less energy-intensive, potentially resulting in a lower cost per unit weight.

Suitability:

- Pellets: Ideal for automated feeding systems in pellet stoves, boilers, and industrial applications due to their uniform size and efficient burning.

- Briquettes: Suitable for manual use in fireplaces, open fires, and some stoves. May be a good option for utilizing waste biomass with minimal processing.

Summary Table:

| Feature | Biomass Pellets | Briquettes |

| Shape | Cylindrical/Cubical | Varied (logs, rectangles) |

| Size | Small diameter (6-12mm) | Larger diameter (50-90mm) |

| Production Process | High pressure & heat | Mechanical/Hydraulic pressure |

| Burning Characteristics | Efficient, consistent, lower ash | Slightly lower efficiency, may require refilling |

| Moisture Content | Lower (below 10%) | Slightly higher (up to 15%) |

| Cost | Generally higher per unit weight | Potentially lower per unit weight |

| Suitability | Automated systems | Manual use (fireplaces, stoves) |

Ultimately, the best choice between biomass pellets and briquettes depends on your specific needs and application. Consider factors like:

- Burning equipment: Pellets are ideal for automated systems, while briquettes work well for manual loading.

- Cost: If budget is a major concern, briquettes might be a more affordable option.

- Availability: Local availability of pellets or briquettes might influence your decision.

- Storage: Lower moisture content of pellets allows easier storage.

Biomass Pellet vs. Briquettes

| Feature | Biomass Pellets | Briquettes |

| Shape | Cylindrical or cubical | Varied (logs, rectangles, etc.) |

| Size | Small diameter (6-12mm) | Larger diameter (50-90mm) |

| Production Process | High pressure & heat with grinding | Mechanical/Hydraulic pressure, sometimes with binder |

| Burning Characteristics | More efficient, consistent, lower ash | Slightly lower efficiency, may require refilling |

| Moisture Content | Lower (below 10%) | Slightly higher (up to 15%) |

| Cost | Generally higher per unit weight | Potentially lower per unit weight |

| Suitability | Automated systems (pellet stoves, boilers) | Manual use (fireplaces, stoves) |

| Storage | Easier due to lower moisture content | May require drier conditions |

| Processing of Biomass | Requires grinding into fine powder | Less processing required pen_spark |