🌱 Biomass Pellet Plant Potential in Mathura, Etawah & Aligarh: Raw Material, Demand & Viability Analysis

✅ Region Overview

The region encompassing Mathura, Etawah, and Aligarh in Uttar Pradesh is agriculturally rich and semi-industrial, offering a strategic opportunity for biomass pellet production due to:

- Abundant agro-residues (mustard husk, wheat straw, sugarcane leaves)

- Availability of wood waste and tree branches from orchard trimmings and storms

- Presence of pellet-consuming industries: Namkeen, Dairy, Boilers, Brick Kilns

🔄 Raw Material Availability and Frequency

| Biomass Material | Source | Availability (Tons/Year) | Frequency | Remarks |

| Mustard Husk | Mustard oil mills (Aligarh, Etawah) | 80,000 – 1,00,000 | Seasonal (Nov–Feb) | Dry & low ash |

| Tree Branches/Wood Waste | Cyclones, pruning (orchards, urban areas) | 40,000 – 60,000 | Intermittent | Requires drying |

| Wheat Straw | Wheat farming (entire belt) | 1,50,000 – 2,00,000 | Seasonal (April–May) | High volatile matter |

| Sugarcane Trash | From Etawah, Hathras, western UP mills | 50,000 – 70,000 | Seasonal (Nov–Apr) | Needs shredding |

| Cotton Stalks | Some belts near Aligarh | 10,000 – 20,000 | Seasonal | Good GCV |

| Press Mud (Dry) | Nearby sugar mills | 5,000 – 10,000 | Available Nov–Mar | Moist, requires blending |

📦 Biomass Pellet Demand Segments

| Consumer Sector | Usage | Preferred Pellet Size | Location | Estimated Demand (TPA) |

| Namkeen Industries | Roasting ovens, dryers | 6mm | Aligarh, Hathras | 5,000 – 8,000 |

| Dairy Plants | Boiler heating, milk drying | 6–8mm | Mathura, Agra | 3,000 – 5,000 |

| Industrial Boilers | Steam generation | 8mm | Etawah belt | 10,000 – 15,000 |

| Pellet Stove Retail | Household heating/cooking | 6mm | Across region | 1,000 – 2,000 |

| Power Plants (co-firing) | Blending with coal | 8–10mm | Ghatampur, Harduaganj | 25,000 – 50,000 |

🚛 Transport Lead & Supply Chain Viability

- Inbound Logistics (Raw Material):

- 20–50 km average radius for biomass collection.

- Seasonal stockpiling required; use balers and tractors.

- Tree branches require shredders or chippers.

- Outbound Logistics (Pellet Supply):

- 50–150 km for industries (diesel trucks, ~₹5–7/km/ton)

- Retail sales via 25–50 kg bags to stove users.

- Low ash pellets preferred; 6mm size for food units.

⚙️ Viability Factors

| Factor | Comment |

| Land Availability | Easily available in outskirts of Etawah/Mathura |

| Skilled Labour | Semi-skilled workforce present |

| Raw Material Supply | Sustainable from agro-forestry cycles |

| Market Proximity | Close to demand centers |

| Govt Support | Eligible under PM Kusum, MNRE bioenergy policy |

🌡️ GCV Values & Mix and Match Recipe (Approx.)

| Raw Material | GCV (kcal/kg) | Ash % | Recipe Ratio | Final GCV (kcal/kg) |

| Mustard Husk | 3,800 – 4,200 | 5 – 7 | 40% | |

| Tree Branches (Dry) | 4,000 – 4,400 | 2 – 4 | 30% | ~4,050 – 4,150 |

| Wheat Straw | 3,600 – 3,800 | 6 – 8 | 20% | |

| Sugarcane Trash | 3,500 – 3,700 | 6 – 10 | 10% |

Note: Recipe optimized for 6mm pellets for namkeen industries and minimal clinker formation in boilers.

✅ Conclusion

The Mathura-Etawah-Aligarh zone presents a strong potential for biomass pellet production due to:

- Abundant, diverse raw materials

- High regional demand for thermal applications

- Affordable logistics within 100–150 km

- Supportive government schemes (e.g., 80JJA tax rebate, bioenergy capital subsidies)

Establishing a 3–5 TPH biomass pellet plant here is viable and sustainable with potential expansion toward Agra, Firozabad, Kanpur for bulk buyers.

⚠️ Disclaimer:

The above data is based on estimations and regional industrial trends. Actual values may vary depending on local agricultural yield, policy changes, and infrastructure updates.

📞 Contact Us for Biomass Solutions

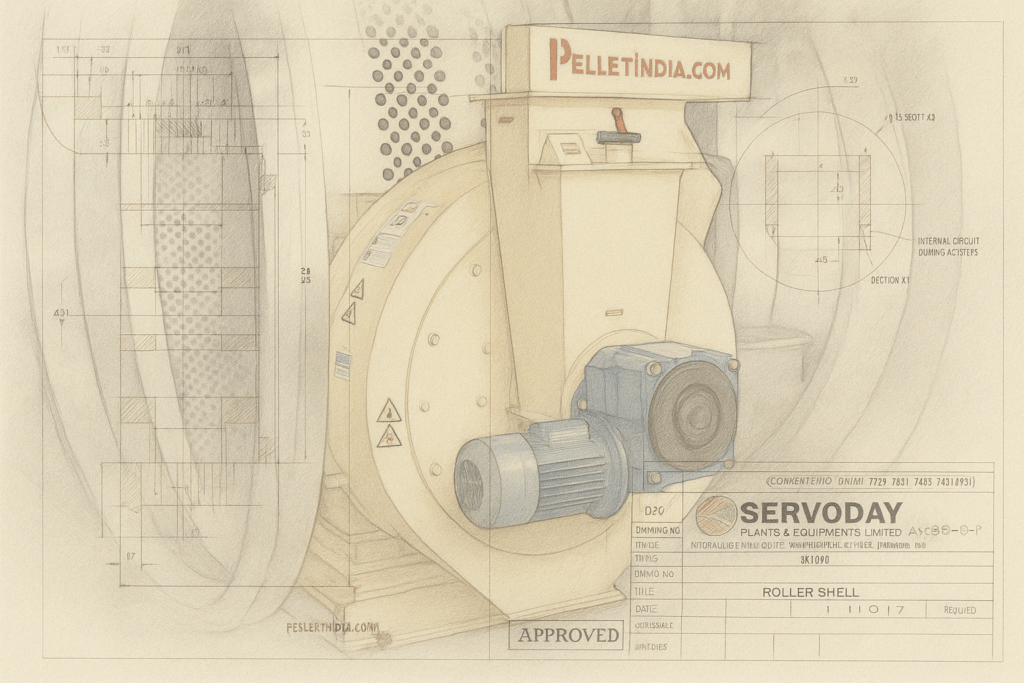

📍 Servoday Plants & Equipments Ltd

📞 +91 9427210483 | +91 9427210484

📧 [email protected]

🌐 www.PelletIndia.com

👤 Contact Person: Sanjay Masuria

📲 WhatsApp: +91 9427210483

From Concept to Commissioning. We are with You.

Our policy is simple and transparent:

No undersized parts, no fraud, no fake components—genuinely serving since 1969. 🚀🔥