What Is the Future of Electric Loaders & Excavators in the Mining Industry?

The mining sector is embracing a sustainable transformation—and electric loaders and excavators are leading the charge. As mining companies aim to reduce emissions, lower costs, and boost efficiency, electric machinery is becoming the preferred alternative to diesel-powered equipment. ⚡ Why Electric Loaders & Excavators Are the Future of Mining 🚜 How ElectricExcavator.in Supports the Mining […]

Continue reading🌱 Inside a PelletIndia Fully Automated Biomass Pellet Plant: Key Machinery & Layout

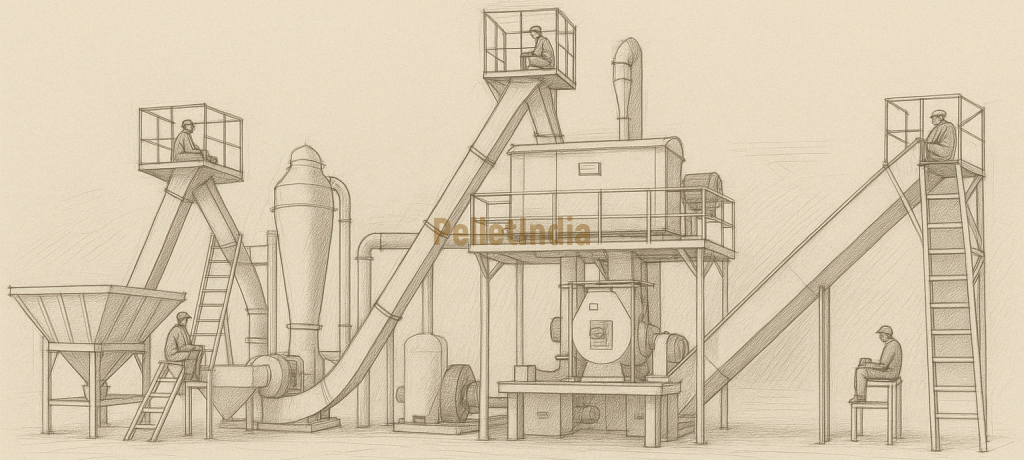

PelletIndia’s 5 TPH Fully Automated Biomass Pellet Plant is a cutting-edge facility designed for high efficiency, minimal human intervention, and consistent pellet quality. This real-world setup integrates smart automation, heavy-duty equipment, and an energy-efficient layout to ensure 24/7 operation with only 2 operators per shift. 🔧 Key Machinery in the 5 TPH Fully Automated Pellet […]

Continue reading🔌 Large Excavators Suitable for Electric Conversion

ElectricExcavator.in provides custom electric conversion solutions for large construction and mining excavators. Below is a curated list of high-power excavator models from renowned brands that are ideally suited for electrification. 🚜 Caterpillar (CAT) Known for durability, high output, and global parts availability. Model Operating Weight Engine HP Key Features CAT 395 ~94,500 kg 543 HP […]

Continue reading🔍 Custom Grab Design: How GrabsIndia Tailors Solutions for Diverse Industries

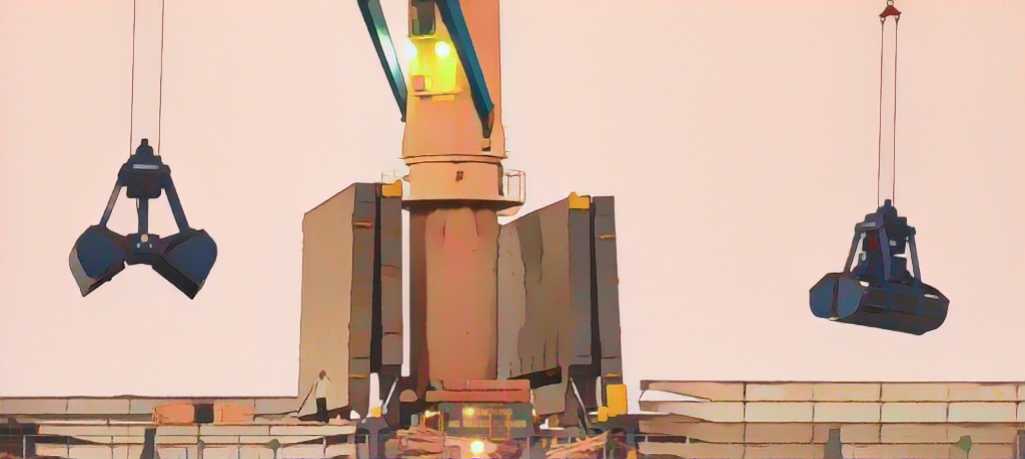

At GrabsIndia, we understand that material handling needs vary significantly across industries. Whether you’re operating at a port terminal, in a steel plant, or within a waste-to-energy facility, our engineering team delivers custom-designed grabs that are optimized for performance, durability, and safety. 🛠️ Types of Grabs We Manufacture GrabsIndia offers a complete range of mechanical […]

Continue reading♻️ What Is the Role of Dewatering Technology in Biomass Processing?

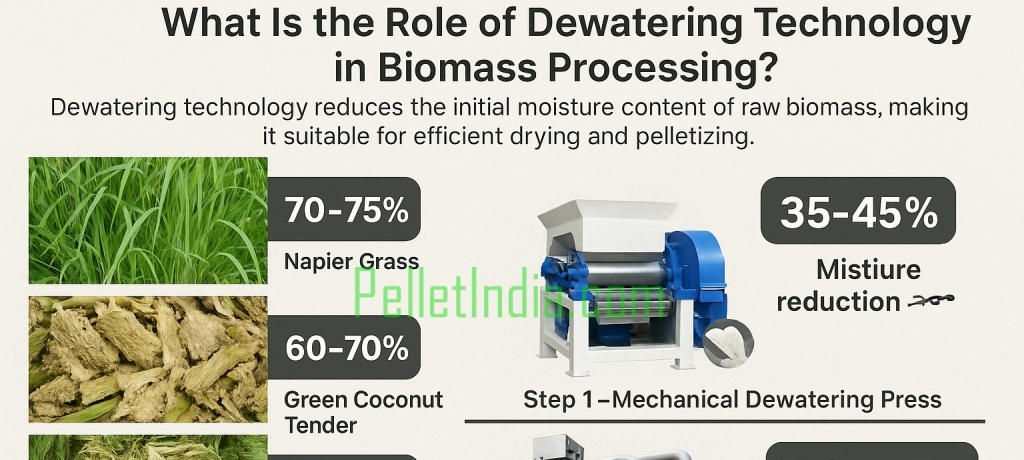

Dewatering technology plays a crucial role in the biomass pellet-making process by reducing the initial moisture content of raw biomass materials, making them suitable for efficient drying and pelletizing. Many high-moisture raw materials—such as Napier Grass, sugarcane bagasse, and green coconut husk—contain 65% to 75% moisture, which is too high for direct pellet production. To […]

Continue reading