Biofuel & Bioenergy Expo 2025 – India’s Largest Biofuel & Bioenergy Exhibition

Description The Biofuel & Bioenergy Expo 2025, organized by Magnifiko Services Pvt. Ltd., is India’s premier event dedicated to biofuel, bioenergy, and sustainable energy innovations. Scheduled from 7th to 9th November 2025, the expo will be held at Shriram Business Park, Vidhan Sabha Road, Raipur, Chhattisgarh, bringing together top industry leaders, investors, policymakers, and innovators […]

Continue readingProcess to Register a Biomass Pellet Plant under MNRE (India)

DESCRIPTIONHere’s a crisp, step-by-step guide to getting your biomass pellet (or torrefied pellet) plant registered for Central Financial Assistance (CFA) under MNRE’s National Bioenergy Programme (Biomass Programme), plus linked portals, current CFA rates, co-firing obligations that create demand, and state-level incentives you can stack. Ministry of New and Renewable Energy DETAILED SUMMARY (How to apply […]

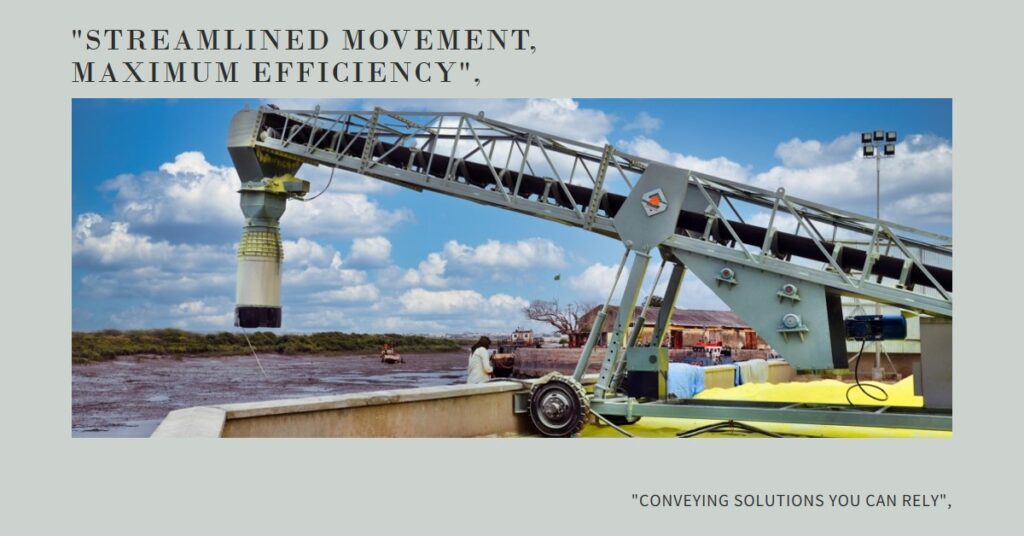

Continue reading🚢 Ship & Barge Bulk Loading Conveyor System by GrabsIndia

Efficient, Reliable & High-Capacity Bulk Material Handling Solutions The Ship & Barge Bulk Loading Conveyor System by GrabsIndia (Servoday Plants & Equipments Limited) is an advanced turnkey solution designed to streamline the transfer of bulk materials from port to vessel. From concept to commissioning, every stage is executed with precision to ensure smooth, continuous, and […]

Continue readingThe Unstoppable Rise of Radio Remote Control Grabs in the Ship & Port Sector

How Radio Remote Control Grabs Are Claiming Their Space in the Ship and Port Sector In the fast-paced world of maritime trade, efficiency and speed are the currency of success. For decades, bulk cargo handling depended on conventional grabs, but these often brought limitations—complex wiring, external power needs, and slower turnaround times. Enter the Radio […]

Continue readingBiogas Outputs from Different Substrates: A Comprehensive Guide

Introduction Biogas is a renewable source of energy generated from the anaerobic digestion of organic materials. The quantity of biogas produced depends greatly on the type of substrate, its moisture content, and composition. Understanding the potential yields of different feedstocks is essential for designing efficient biogas plants and maximizing energy recovery. Below is a detailed […]

Continue reading