🌿 Forestry Waste Availability in India (District-Wise), Its Types, Utilization Procedure & Mobile Pellet Solutions by PelletIndia

✅ Wide Summary: Forestry Waste Generation in India (State & District Wise) India generates a significant amount of forestry waste annually, which includes branches, bark, sawdust, twigs, leaves, stumps, off-cuts, and thinning residues. Forestry waste arises due to logging operations, forest thinning, plantation clearances, storm-felled trees, and wood processing industries. Below is a summary of […]

Continue readingState-Specific Carbon Credit & REC Incentives for Biomass Users in Tamil Nadu, Karnataka, and Rajasthan

This comprehensive guide explains carbon credit and REC incentives for biomass users in Tamil Nadu, Karnataka, and Rajasthan. It covers financial benefits, biomass sourcing districts, and step-by-step procedures to register, generate, and trade environmental credits. With government-backed schemes and MNRE support, biomass producers can reduce costs and monetize green energy efforts. Ideal for renewable energy […]

Continue readingBiomass Energy Scope in Andaman & Nicobar

The scope for biomass energy in the Andaman and Nicobar Islands is promising, but it requires strategic planning due to geographical, environmental, and logistical challenges. Here’s a breakdown of its potential: 🌿 1. Biomass Availability in Andaman & Nicobar ✅ Sources of Biomass: ⚡ 2. Energy Demand & Opportunity 🌱 3. Government Support & Sustainability […]

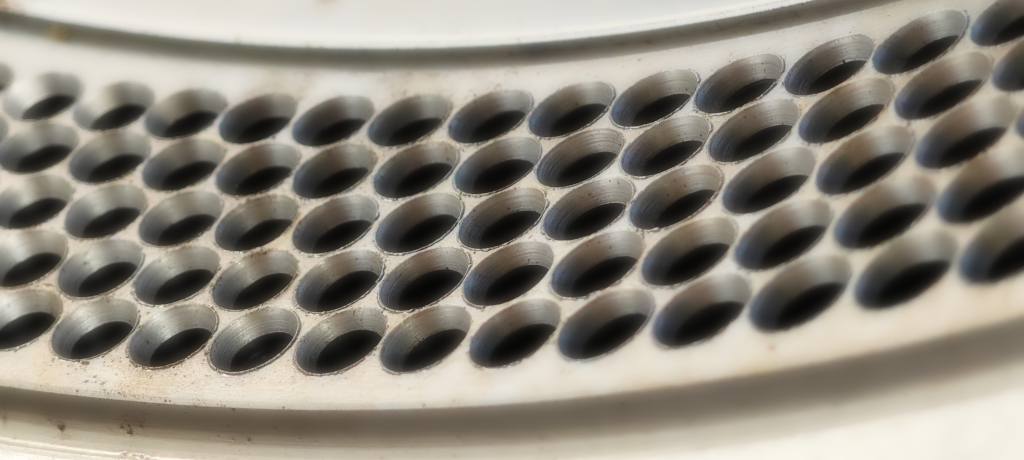

Continue readingRing Die Pellet Mill by PelletIndia – Built for Performance, Powered by Trust

🇮🇳 100% Made in India✅ Maximum Efficiency | 🔧 Low Maintenance | 🔩 Long-Lasting Parts📈 Available in 1 TPH, 2 TPH, 3 TPH, and 5 TPH Models🛡️ Your Trust, Our Guarantee🌐 www.PelletIndia.com📞 Contact: +91 9427210483 📞 Contact Us for Biomass Solutions📍 Servoday Plants & Equipments Ltd📞 +91 9427210483 | +91 9427210484📧 [email protected]🌐 www.PelletIndia.com👤 Contact Person: […]

Continue readingWhat is the NIC Code for Biomass Pellet and Biofuel Manufacturing in India?

✅ NIC Codes Related to Biomass (Pellets, Briquettes, Biofuels) And 🏛️ Procedure to Apply or Endorse NIC Codes in Government Records ✅ NIC CODES RELATED TO BIOMASS INDUSTRIES 🧾 The Code to Remember: NIC Code is important to ensure the right recognition and avail benefits offered by the government to take your biomass business further.✅ […]

Continue reading