Can rice straw alone be used for pellet making or should it be mixed?

✅ Can We Make Pellets from Only Rice Straw? Yes, it’s technically possible, but not advisable for the following reasons: 🔴 Challenges with Using Only Rice Straw: ✅ Should You Use a Mix-and-Match Recipe? Yes. Mixing rice straw with other biomass is the preferred and practical approach. 👍 Benefits of Mixing: 🔍 Suggested Mix Ratios […]

Continue reading🎉 SERVODAY – Celebrating 56 Years

SERVODAY – Celebrating 56 Years Since 1969 – A Legacy of Innovation & Excellence 56 YEARS of TRUST, TECHNOLOGY & TRANSFORMATION Pioneers in: • Biomass Pellet Plants • Electric Excavators • Bulk Material Handling Grabs • Customized Engineering Solutions From Jamnagar, Gujarat to the World Powering Green Energy & Smart Engineering Thank you to our […]

Continue reading🌱 Biomass Pellet Plant Potential in Mathura, Etawah & Aligarh: Raw Material, Demand & Viability Analysis

✅ Region Overview The region encompassing Mathura, Etawah, and Aligarh in Uttar Pradesh is agriculturally rich and semi-industrial, offering a strategic opportunity for biomass pellet production due to: 🔄 Raw Material Availability and Frequency Biomass Material Source Availability (Tons/Year) Frequency Remarks Mustard Husk Mustard oil mills (Aligarh, Etawah) 80,000 – 1,00,000 Seasonal (Nov–Feb) Dry & […]

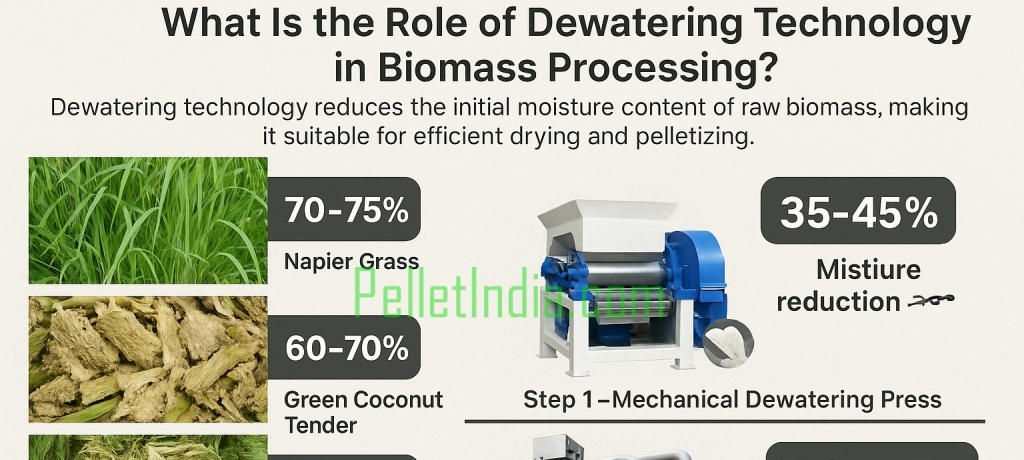

Continue reading♻️ What Is the Role of Dewatering Technology in Biomass Processing?

Dewatering technology plays a crucial role in the biomass pellet-making process by reducing the initial moisture content of raw biomass materials, making them suitable for efficient drying and pelletizing. Many high-moisture raw materials—such as Napier Grass, sugarcane bagasse, and green coconut husk—contain 65% to 75% moisture, which is too high for direct pellet production. To […]

Continue reading📘 CBG Digestate Pellets – Feasibility, Formulation & Market Insights

🔬 What Happens to Napier Grass After CBG Process? ⚖️ GCV Comparison Before & After CBG Material Type GCV (kcal/kg) Natural Napier Grass Pellet 3,800 – 4,200 CBG Digestate Pellet (Pelletized) 2,100 – 2,600 Why GCV Drops: 🔧 Mix-and-Match Recipes to Improve Pellet Quality Recipe Type Ingredients Blend Ratio GCV (kcal/kg) Purpose Premium Fuel Napier […]

Continue reading