Introduction:

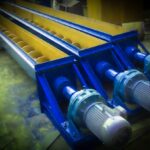

The auger conveyor is a specialized material handling system designed to efficiently transport biomass materials. It is ideal for industries that process wood chips, sawdust, rice husk, wheat straw, and other organic waste. Constructed using either stainless steel (SS) or mild steel (MS), the conveyor offers a balance between durability and cost-effectiveness, depending on the application. Capable of handling up to 20 tons per hour, the auger conveyor is a robust solution for high-capacity operations. Its compact design allows for customization to meet specific installation requirements. With its ability to handle various material densities, the auger conveyor ensures reliable transport with minimal material degradation.

Features:

The auger conveyor boasts several key features that make it an ideal choice for biomass handling. Available in both U-shaped and tubular trough designs, it can be customized to include an optional cover for dust control. The auger diameter ranges from 150mm to 500mm, with screw pitch adjustments between 150mm and 300mm, depending on material flow rates. With the flexibility to be installed horizontally or inclined up to 45 degrees, it can easily adapt to different site conditions. The conveyor’s motor power ranges from 5 kW to 30 kW, ensuring efficient operation across various capacities. Additionally, the conveyor is available with a polished finish for SS or a painted finish for MS, enhancing durability and corrosion resistance.

Uses:

The auger conveyor serves a variety of applications, primarily in the biomass and renewable energy sectors. It is commonly used to transport materials such as wood chips, agricultural residues, and forestry waste to processing plants or energy facilities. Its high-capacity design makes it suitable for large-scale biomass production and handling operations. Whether installed as part of a horizontal or inclined system, it provides consistent and reliable material flow, making it essential for efficient biomass processing. Additionally, the conveyor can handle multiple discharge points and flow control gates, offering flexibility for operations requiring precise material distribution.

Raw materials:

Biomass materials handled by auger conveyors include wood chips, sawdust, rice husk, wheat straw, and bagasse. Other materials such as Napier grass, corn stalks, and coconut husk and shell are also easily transported by the system. Agricultural residues like coffee husk, peanut shells, and cotton stalks, as well as forestry waste like mulberry sticks, sunflower stalks, and bamboo dust, are efficiently handled. Sugarcane leaves, paddy straw, and palm husk further exemplify the conveyor’s adaptability to various biomass types. Whether handling light, fluffy materials or denser organic matter, the auger conveyor provides efficient and reliable transport.