What are the most suitable raw materials for manufacturing compressed pallets, and how can they be optimized for cost-effective production?

Suitable Raw Materials for Compressed Pallets Wood-Based Materials These materials are the most commonly used due to their natural fibrous structure and compressibility: Agricultural Residues These materials are cost-effective and readily available as by-products of agricultural activities: Specialized Materials Key Benefits of Using These Materials Considerations for Processing Recommended Blends for Specific Applications Application Material […]

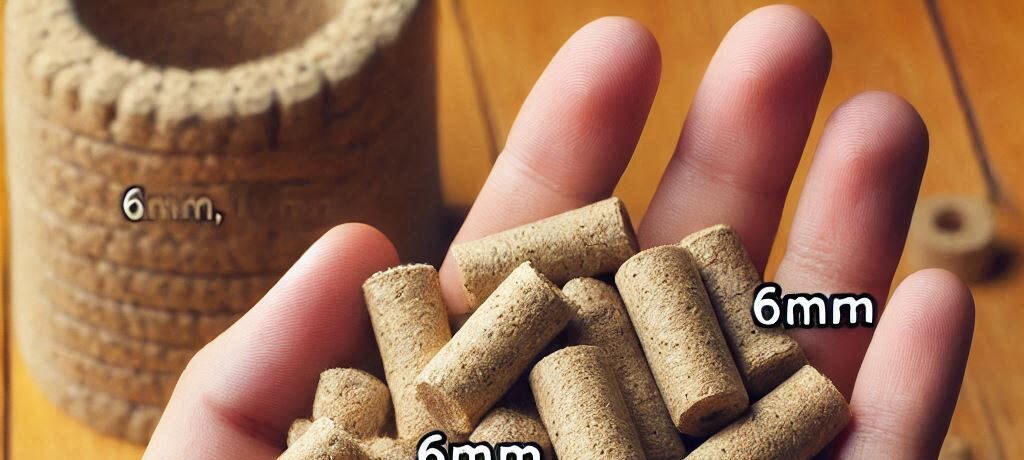

Continue readingWhat are the benefits of different biomass pellet sizes (6mm, 8mm, 10mm, 12mm) for specific applications and materials?

The different pellet diameters (6mm, 8mm, 10mm, and 12mm) are chosen based on the specific application, type of biomass material, and combustion system. Below is a detailed explanation of why different pellet sizes are used and their relevance for various biomass materials along with their Gross Calorific Value (GCV): 🌟 Pellet Sizes and Applications 🌟 […]

Continue readingWhat are the best Indian bamboo varieties for making biomass pellets and chips?

Indian bamboo varieties suitable for making bamboo chips and pellets, along with their growing regions and technical characteristics: 1. Bambusa Tulda (Indian Timber Bamboo) साल बांस (Sal Bans) 2. Dendrocalamus Strictus (Solid Bamboo) ठोस बांस (Thos Bans) 3. Bambusa Balcooa (Balcooa Bamboo) बलकुआ बांस (Balukua Bans) 4. Bambusa Nutans (Nutans Bamboo) नुतान बांस (Nutans Bans) […]

Continue readingWhat are the calorific values of different biomass fuels LHV-HHV for energy applications?

The Lower Heating Value (LHV) and Higher Heating Value (HHV) are measures of the energy content of a fuel, but they differ in how they account for the water vapor produced during combustion. Here’s the difference: 1. Higher Heating Value (HHV): 2. Lower Heating Value (LHV): Key Differences: Aspect HHV LHV Water Vapor Includes latent […]

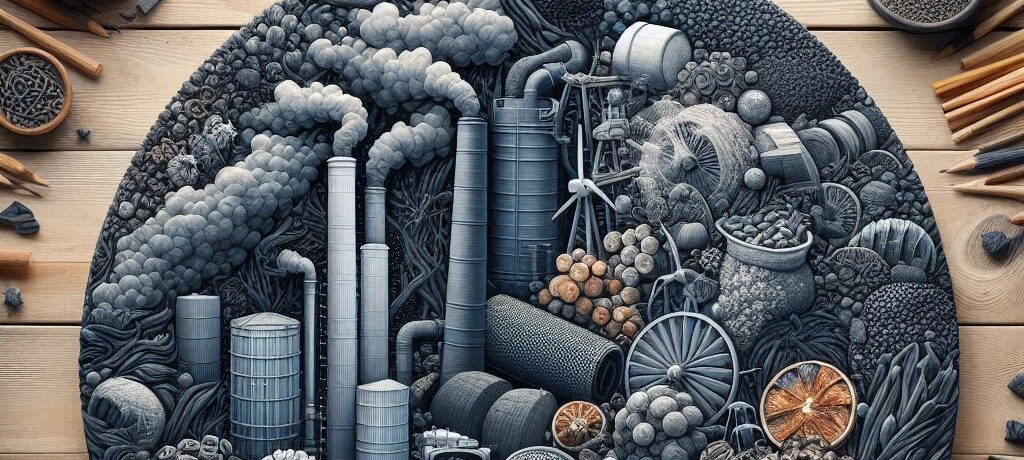

Continue readingCharcoal, Carbonization, and Torrefaction of biomass materials relate to their processing temperatures, chemical properties, and end uses:

1. Charcoal Production Process: Chemical Properties: Physical Properties: Applications: Environmental Impact: 2. Carbonization Overview: Process Details: Chemical Changes: Products: Applications: Environmental Benefits: 3. Torrefaction Process Characteristics: Chemical and Physical Changes: Process Steps: Product Characteristics: Applications: Advantages: Key Differences Summary: Feature Charcoal Carbonization Torrefaction Process Temperature 500–700°C 300–600°C 200–300°C Fixed Carbon High (70–90%) Medium to high […]

Continue reading