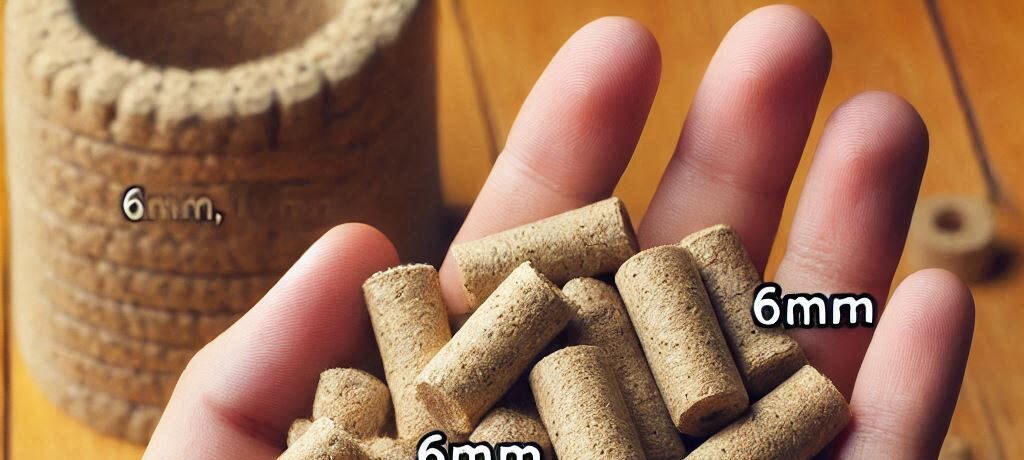

What are the benefits of different biomass pellet sizes (6mm, 8mm, 10mm, 12mm) for specific applications and materials?

The different pellet diameters (6mm, 8mm, 10mm, and 12mm) are chosen based on the specific application, type of biomass material, and combustion system. Below is a detailed explanation of why different pellet sizes are used and their relevance for various biomass materials along with their Gross Calorific Value (GCV): 🌟 Pellet Sizes and Applications 🌟 […]

Continue readingWhat are the best Indian bamboo varieties for making biomass pellets and chips?

Indian bamboo varieties suitable for making bamboo chips and pellets, along with their growing regions and technical characteristics: 1. Bambusa Tulda (Indian Timber Bamboo) साल बांस (Sal Bans) 2. Dendrocalamus Strictus (Solid Bamboo) ठोस बांस (Thos Bans) 3. Bambusa Balcooa (Balcooa Bamboo) बलकुआ बांस (Balukua Bans) 4. Bambusa Nutans (Nutans Bamboo) नुतान बांस (Nutans Bans) […]

Continue readingHow Process Flow of RDF Pellet Production Line?

The process flow of an RDF pellet production line shares some similarities with the briquetting process but has key differences. Here’s a breakdown: 1. Pre-treatment: 2. Grinding: 3. Pelleting: 4. Post-processing: Additional considerations: Benefits of RDF pellets: Challenges of RDF pellets: RDF Pellet Machine Ring die pellet machine is one of the most stable pellet […]

Continue readingWhy Make a RDF Pellet or Briquette?

There are several reasons why someone might choose to make an RDF pellet or briquette: Improved Handling: Enhanced Combustion Properties: Environmental Benefits: Economic Advantages: However, it’s important to consider:

Continue readingWhat is RDF/SFR/RPF Pellet or Briquettes?

RDF/SFR/RPF pellets and briquettes are all related to waste management and renewable energy. While they share some similarities, they also have distinct characteristics: RDF: SFR: RPF: Pellets and Briquettes: In summary:

Continue reading