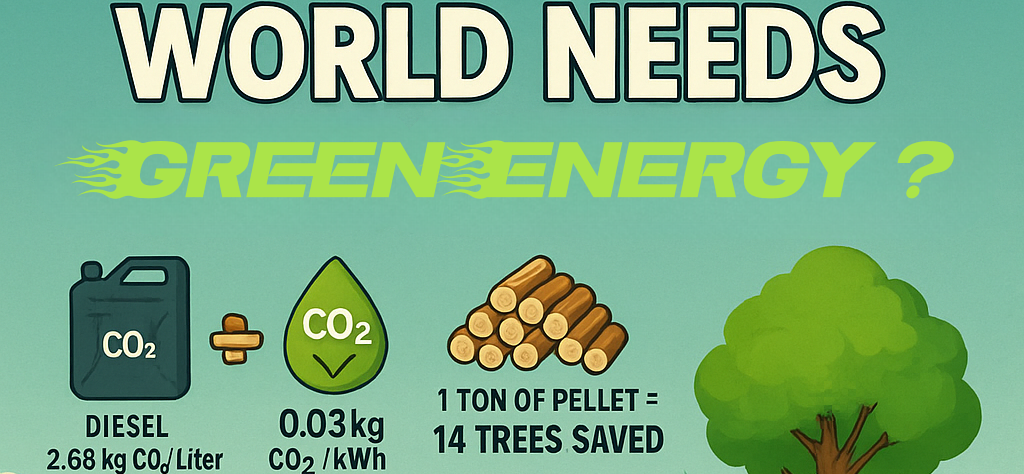

🌍 WORLD NEEDS GREEN ENERGY – WHY? 💚⚡

✨ Description The world is moving toward sustainable and cleaner energy solutions. Traditional fossil fuels like diesel emit harmful greenhouse gases, while biomass pellets offer a carbon-neutral, eco-friendly, and efficient alternative. By replacing diesel and coal with engineered wood pellets, industries can save trees, cut emissions, and enjoy stable, low-cost energy. 🔎 Detailed Summary 🚫 […]

Continue reading🔥 How Can You Improve the Quality and Profitability of Parali (Paddy Straw) Biomass Pellets? 💰♻️🌾

Making Biomass Pellets from Parali (Paddy Straw): Challenges, Solutions & Cost Analysis Challenges of Parali Pelletization 1️⃣ Low Lignin Content: 2️⃣ High Silica Content: Solutions to Improve Parali Pellet Quality ✅ Mixing with High-Lignin Biomass – Adding bagasse, sawdust, wood chips, mustard stalk improves binding.✅ Using Binders – Molasses, starch, or lignosulfonates enhance pellet durability.✅ […]

Continue readingWhat is Volatile Matter (VM) in Biomass Pellet?

🔥 Biomass Material: Volatile Matter, GCV, and Industry Applications 🌱 💡 Which Biomass Material is Best for Your Industry? Volatile Matter (VM) refers to the gases and vapors released from biomass when it is heated before complete combustion. It consists mainly of hydrocarbons, carbon monoxide, and other light gases, affecting combustion behavior in different industries. […]

Continue reading🌿 High-Silica or Low-Lignin Biomass Materials and Their Challenges in Pellet/Briquette Production

🔎 What are the challenges of high-silica biomass in pellet production? Characteristics of High-Silica Biomass: ✔️ High Ash Content: Leads to slagging and fouling in combustion systems.✔️ Abrasive Nature: Causes excessive wear on pellet mill dies and rollers.✔️ Low Energy Density: Results in poor combustion efficiency.✔️ Hard to Pelletize: High friction makes densification difficult. ⚠️ […]

Continue reading💡 Which fuel is the best choice for industrial heating – Biomass Pellets, LPG, or PNG?

🔥 Biomass Pellets vs LPG/PNG Gas: Ultimate Comparison for Industrial Heating & Cost Savings! Point-to-Point Fuel Comparison: Biomass Pellets vs LPG/PNG Gas Feature Biomass Pellets🌿 LPG (Liquefied Petroleum Gas) 🔥 PNG (Piped Natural Gas) 🔥 Calorific Value (GCV) 4000 kcal/kg (17 MJ/kg) 11,000-12,000 kcal/kg (46-51 MJ/kg) 9,080 kcal/m³ (38 MJ/m³) Cost per kg/m³ ₹9.50/kg ✅ […]

Continue reading